Features

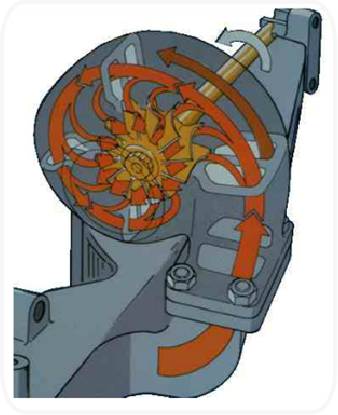

How supercharger works

●The faster the speed, the more air is sucked in

●After entering the pressure shell, the air passes through the pressure impeller and expansion zone

●Pressing the impeller and diffuser increases the air pressure and presses it into the engine

●There are sealing rings at both the vortex and pressure ends of the turbocharger

●The function of the sealing ring is to effectively seal to prevent exhaust gas and air from entering the intermediate shell and prevent oil leakage

●The surface of the vortex end pressure end hole cavity must be smooth and free of scratches

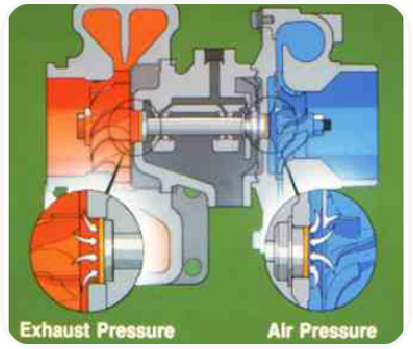

Turbine end

●The turbine casing is connected to the engine exhaust pipe

●Exhaust gas drives the turbine wheel in the turbine housing

●The turbine wheel drives the pressure impeller on the coaxial shaft

Compressor end

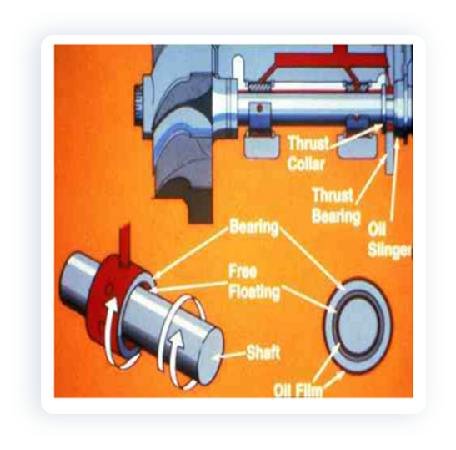

bearing system

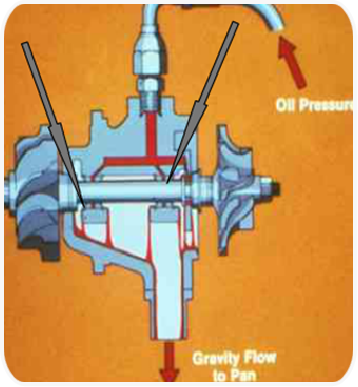

●The turbocharger uses the same oil as the engine

●Engine oil serves as both lubricating and cooling oil

●After the oil is pressurized, it enters the intermediate housing and passes through the floating bearing and thrust system

Sealing system

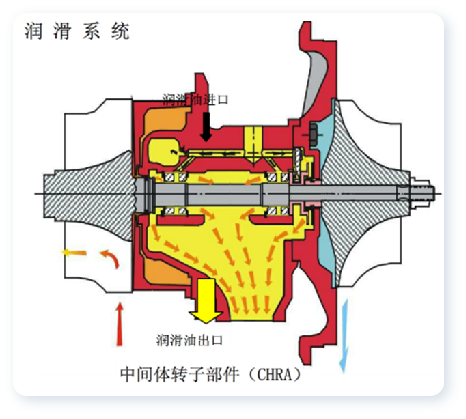

Lubrication structure of turbocharger

●Lubrication system: The 0.2-0.4MPa pressure lubricating oil flowing into the engine lubrication system flows into the floating bearing and thrust bearing through the oil inlet on the intermediate shell, while cooling various components of the rotor assembly. Finally, the lubricating oil is discharged by gravity from the oil return hole of the intermediate shell.

●The turbocharger relies on these two layers of oil film to operate at speeds of over 100000 revolutions per minute.

●The turbocharger relies on these two layers of oil film to operate at speeds of over 100000 revolutions per minute.

●Lubrication failure is fatal for turbochargers!

The role of the lubrication system

□Cooling heat from turbine operation

□Provide lubrication to the bearing system

□Provide oil film support for rotor dynamic balance

When the turbocharger operates at high speed, a large amount of heat is generated, and at the same time, a large amount of heat is transferred to the intermediate housing at the turbine end. Oil can take away some of the heat, thereby reducing the temperature of the intermediate housing and bearings

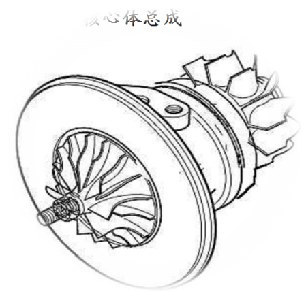

The basic structure of a turbocharger

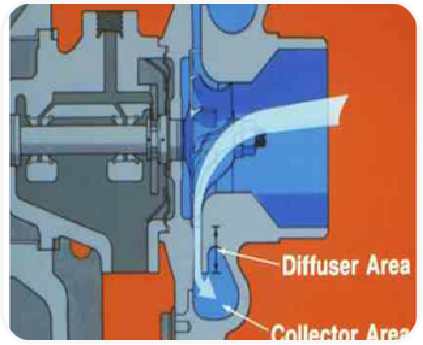

Compressor section

Compressor part: including compressor impeller, diffuser and compressor casing. The compressor impeller sucks in the ambient air through the air filter, diffuses through the diffuser, and then collects it from the compressor housing into the engine cylinder.

Turbine section

Turbine part: The turbine part is composed of a turbine casing and a turbine impeller. The exhaust gas sent by the diesel engine enters the turbine casing through the exhaust pipe and flows in a certain direction to the turbine impeller, causing the turbine to rotate at high speed

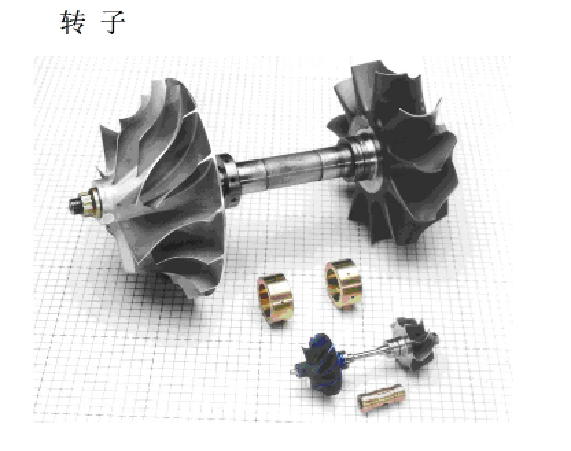

Turbine rotor assembly

The turbine rotor, compressor impeller, and corresponding shaft components form the rotor assembly. Both the turbine rotor and compressor impeller undergo precise single body balancing to ensure the normal operation of the rotor assembly at high speed. The turbine rotor adopts an internal support form, and the floating bearing is located in the middle body between the two impellers. The axial force of the rotor is borne by the thrust bearing.

During normal operation, the load on the bearings is very small.

The intermediate housing is the supporting mechanism of the turbocharger. The rear plate of the diffuser and the turbine housing are respectively fixed on the intermediate with bolts. The radial load and axial load of the rotor are finally transferred to the intermediate through the floating bearing and thrust bearing. The intermediate is also the lubrication and cooling device of the turbocharger, and its oil inlet hole is connected to the main oil channel of the engine lubrication system. In addition to lubricating the floating bearings and thrust bearings, lubricating oil will also be carried away by the heat transferred from the exhaust gas, ensuring the reliable operation of the turbocharger.